|

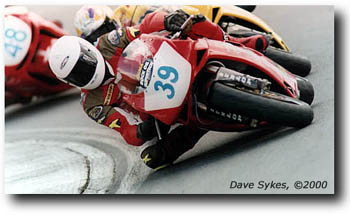

In the UK in 2000 a little tuning shop (us!) decided to go British

Championship Supersport racing.

Supersport is a lot closer to road bikes than Superbike so, just like the production series in 1999 what we learned would be of direct relevance to the street bikes we deal with daily.

In 2000 British Championship racing meant we would be going head to head with Factory

Hondas and Sundry Importer Teams in a televised series.

This was not a sideshow or 'Saturday race' this was one of the main parts of the British championship. It is a 'win on Sunday, sell on Monday' class, it is very important to the manufacturers. Our overall budget was to be about half of what Honda were paying Jim Moodie to simply ride their CBR600.

We bought a 748RS. Here you can see the photos of the bike 'on delivery'. As you can see it is a stripped down version of the street

bike with lightweight bodywork, race only wiring loom, exposed Cam belts and internal engine modifications that are inline with the FIM world Supersport rule book. We bought a 748RS. Here you can see the photos of the bike 'on delivery'. As you can see it is a stripped down version of the street

bike with lightweight bodywork, race only wiring loom, exposed Cam belts and internal engine modifications that are inline with the FIM world Supersport rule book.

All civilised countries and the UK use these same regulations for their National Supersport class.

Pitching 750 twins against 600 fours the Supersport class is one of the most closely fought over in the world, the Ducati had fallen behind

over the last few years; the 748RS was the chosen vehicle for their re-entry onto the centre stage.

From the start we knew there would be little room in the budget so we elected to run like a

privateer 250 team. Small van (bloody fast third hand Merc Sprinter actually) and a borrowed 1965 GP (honest, real GP, real 1965!) awning; three people max, with a rider on his way up and

not yet being paid - no semi trailers, hospitality units and paddock totty for us (One day….).

We made several important decisions; we would be entirely independent of the British trade,

everybody else uses bought in engine preparation and suspension, we would build our own. The reason for doing a year at this level, even on a shoestring Budget, was to prove that we can build

Ducati's, their motors and set them up with the best there is.

As expected not everything went to plan, there are many things involved in getting a racing motorcycle to the front of a race that would be decided by things completely out

of our control. Despite promises we were not allowed to have full choice of tyres, we did not have the money to test as much as we would like, and there were simply too many costly crashes. As expected not everything went to plan, there are many things involved in getting a racing motorcycle to the front of a race that would be decided by things completely out

of our control. Despite promises we were not allowed to have full choice of tyres, we did not have the money to test as much as we would like, and there were simply too many costly crashes.

But we did all the races we could afford, and on one great weekend in May we

proved our point, Jonesey qualified the bike second (ahem, in front of the previously mentioned Jim Moodie) and finished sixth in a foreshortened race. We always got in the

top five for speed; by the end of the year we were always qualifying in the top ten and at least once were the first Ducati. We

had one mechanical problem all year (Rider had trouble changing down the box, we are still looking for the fault).

The article that follows is a technical comparison of the main differences between the Racing

Ducati 748RS and the road going 748R on which it is based. I have included the relevant parts of the FIM rule book where appropriate (in italics) and sought to show actually how close the road

bike is to the racer and to run through the different ways the two bikes are set up and the reasons for the differences. The tech specification of the bike is set out here and a full copy of the Supersport pages of the 2000 FIM Technical rulebook can be found here.

The purpose of Sports Production racing

- To encourage competition between machines of similar potential power, but with different

engine sizes and configurations.

- To use in competition, machines with the appearance as close to production as possible.

- To provide a racing class with machines available in adequate quantities through normal

commercial channels.

- To allow freedom to the tuner.

- To provide cost limiting factors.

- To provide interest to the after-market suppliers to be involved in competition activities.

- To maintain speed and horsepower at a safe level.

01.58 DISCIPLINE SPECIFICATIONS - SUPERSPORT

VERYTHING THAT IS NOT AUTHORISED AND PRESCRIBED IN THIS RULE IS STRICTLY

FORBIDDEN

Supersport motorcycles require an FIM homologation (see Art. 01.62). All motorcycles must

comply in every respect with all the requirements for Road Racing as specified in the Road Racing Technical Rules, unless it is equipped as such on the homologated machine.

The appearance from both front, rear and the profile of Supersport motorcycles must (except

when otherwise stated) conform to the homologated shape (as originally produced by the manufacturer).

|

Supersport:

|

400 cc - 600 cc

|

4-stroke

|

4 cylinders

|

|

|

600 cc - 750 cc

|

4-stroke

|

2 cylinders

|

Ducati released its long awaited update for the 748SPS in late 1999 called the 748R. The bike featured the first production 'big airbox' design. The box is designed to give both a larger

quantity of nice cold stopped air and a lower frequency pulse to assist the spread of the power band. New larger 54mm throttle bodies are inside the box and feature some very expensive

'shower' style injectors above the butterflies. There is no secondary injector. Just like the early years of the 748SP/SPS, a race prepared version, the 748RS was also released.

The main new parts on the 748R are a motor based on the 996; bigger, stronger, cases bigger

port cylinder heads and larger valves. Designed to stand the 155hp of the 996 racers the cases were as strong as a rock. As mentioned above the other addition was the large airbox and a

modified frame to get the new box in (the frame is the same as that homologated with the Foggy replica in 1998; on that occasion though you still had the old airbox design).

Engine Mods .

58.03.20 Cylinder Head

- Cylinder head must be as homologated. The following modifications are allowed.

- Porting and polishing of the cylinder head normally associated with individual tuning such

as gas flowing or repair of the cylinder head, including the combustion chamber is allowed. Welding is not allowed.

- The compression ratio is free.

- The combustion chamber may be modified.

- The valves may be altered or replaced. The material may be changed. Maximum diameter

and minimum weight must remain as homologated. The use of titanium valves is not allowed.

- The valve seats must remain as homologated. Modifications are allowed.

- The valve guide must remain as homologated. Modifications in the port area are allowed.

- Valve springs can be changed.

- The valve retainers must remain as originally produced by the manufacturer for the homologated machine.

58.03.21 Camshaft

- The method of drive must remain as homologated.

- The duration is free but the lift must remain as homologated.

- The cam chain or cam belt tensioning device(s) are free.

58.03.22 Cam Sprockets

- Cam sprockets can be modified or replaced to allow the degreeing of camshafts.

58.03.26 Pistons

- Pistons must remain as homologated.

- Polishing and lightening is not allowed.

The 748R has the same weight 36mm valves as the 748RS. The valves are different however, the racer comes with chrome topped Menon racing valves. These are very tough one-piece

valves that are designed to take the violence dished out by the Ducati Racing cams. The old way to make power in a four stroke was to bang bigger valves open for longer and longer periods.

These long duration cams allowed both inlet and exhaust valves to be open together for extended periods (known as overlap). Without help from the inlet and exhaust systems these cams would

be pretty hopeless. Inlet and exhaust plumbing was tuned to make the system work well, but the effect was a lot of power focused into a very small band.

To ride a race circuit quickly these days the rider needs an easily accessible broad power band

(the sort you would have considered good for collecting a loaf from the shops just a few years ago). Use an old style narrow band and you will be left behind very easily, even if the peak

horsepower number is better. Powerband width is the name of the game; the ability to open the throttle and have power immediately available. This lets the rider to load up the suspension

whenever he wishes, controlling chassis attitude and allowing far higher corner and exit speeds, this has been our mantra on all our bikes. Ducati's solution is to keep cam duration down but to

open and close big valves with big ports very, very quickly; a true Desmo solution.

Our 748 RS was delivered with spare inlet cams and strict instructions to remove the ones

assembled in the motor before it was run, these cams (type 00E) were simply too violent with valves self destructing after a couple of hours running. We replaced them with the slightly less

aggressive pieces supplied by Ducati. We lost four degrees of duration in this swap, but we also got a set of valves that would last on a race circuit for 750km. Cam timing (at 1mm lift) is, Intake

Opening 30° Before T.D.C. Closing 62° After B.D.C. Exhaust Opening 74° Before B.D.C. Closing 38° After T.D.C. These numbers give little real feel for speed at which the valve is lifted and shut

but, the recommendation from Ducati to replace not only the valves but the closing rockers at 750 km should give some idea of the abuse dealt out.

After 750 km of racing use the chrome round the retaining ring groove is usually starting to break

up. Some query the use of chrome on the valve but it provides a hard surface and greater resistance to mushrooming. Indeed I know of several after market supplied big valves for

Ducati's that are perfectly good valves in normal valve spring engines or even with gentle old style long duration Ducati cams. But in the latest generation of snap open – slam shut Desmo

race engines the tops of these valves, the area above the half rings that locate the closing rockers, would mushroom and could fail. Like most things though this is probably not a problem unless

you are trying to beat the works Honda's.

The FIM rulebook is designed to be easy to scrutineer, checking cam lift is easy, and checking

duration is more complex, so the rulebook insists on standard cam lift and standard pistons. Ducati built themselves room to move by giving the bike 12.5mm lift on inlet and 10.5mm on

exhaust (This is nearly 25% more lift the on a Biposto cam!!). You cannot extend the duration of a cam very far if you cannot make room for it by making the valve cutaways in the top of the

piston bigger, so the logic here is that racing cam duration will be limited by road piston design, well until someone makes a limited run 1000 bike special anyway………. (So what is a CBR600 Sport anyway?).

To go with the Valves the street engine has high lift, but short duration cams. Cam timing (at

1mm lift) is (Racer in Brackets), Intake Opening 20 (30)° Before T.D.C. Closing 60 (62)° After B.D.C. Exhaust Opening 62(74)° Before B.D.C. Closing 38(38)° After T.D.C. As has been

mentioned elsewhere however the road cams get to maximum lift and come back onto the seat comparatively slowly.

The roadbike comes with very small ports, the same sort of size you would expect with the old

33mm inlet valves. The racer however is ported right out to the 36mm valve seat edge. The ports on the racer are quite a sight, especially as this is a mere 748. (Contact us if you want to be

the first one with a big ported standard cammed 853 version: this will be a superb bit of kit.)

The total power producing mods are the cams the valves and the porting, as well as a very classy

54mm lightweight Termignoni exhaust system. The rest of the bikes power producing parts are standard, you better believe though we spent some time getting the engines built properly.

Ducati delivered the engines in the time honoured 'built up because it's the best way to

get the bits into the shipping crate' style. As delivered we found a bit of a rush job, far below the current road bike build quality. Cranks needed re-preloading, the oilways

needed to be checked (some oilways got forgotten !!!!) and the gearbox and associated parts needed Superteching. Once this was done and the new cams were in and timed we were running in.

58.03.18 Fuel Injection System

- Throttle bodies must be standard units as on the homologated model.

- The injectors must be standard units as on the homologated motorcycle.

- Bell mouths may be altered or replaced from those fitted by the manufacturer on the homologated machine.

- Variable length fuel injection intake tract devices that function while the engine is operating

are not allowed.

- Butterfly cannot be changed or modified.

- No modifications of fuel pump or pressure regulator are allowed.

- The fuel injection management computer chip (EPROM) may be changed.

- Fuel pump and fuel pressure regulator must remain as homologated.

We use FIM re-programmable software to allow adjustment of the EPROM fuel map 'in the bike'.

You may think that one cannot adjust an EPROM and you would be right, but Duane Mitchell (FIM) is a bloody genius and has developed a way of accessing, via the EPROM, spare memory in the

Computer itself that allows adjustments of the fuelling and timing 'in situ'. This greatly helps fast fuelling changes be they in the dyno room or in pit lane. Ducati came up with a series of new

versions of the fuel map as they tested the works bikes and during the year we changed a few things but the MK2 EPROM proved to be very good.

However there were places like Mallory where the 'dead stop hairpin followed by a second gear

flip flop chicane' sequence played Havoc with the injection system. We decided that fuel was gathering on the back of the butterfly's in the shut throttle part of the corner and then getting

dumped down the port in a big gulp when the throttle was banged open. We adjusted the mixture but were still looking for the precise settings when we ran out of practice time. This experience

was a classic demonstration of how a good datalogger would have helped us. If we could have isolated the precise throttle openings and rev bands for the important parts of this sequence we

could have adjusted the mixture 'just so' really quickly.

We tried a few different settings on cams and the effect of these changes can be seen on the HP and torque dynocharts above and below. Dyno run 011 is a standard Ducati 748R after a Full

Monty set up (Hi Harald!) run 021 was how we ran the bike for most of the year and run 041 was a setting we experimented with for better 'off the corner' acceleration. We can set the bike to this

spec in under five minutes. This latter curve picks up stronger, just two or three horsepower, but every little helps. Out of corners 8k up to 11.5k this gives more drive but sacrifices a few hp at

the very top. Later in the year analysis of our Stack revcounters memory showed the bike being used a lot more in this zone than at the very top. You can see how the concentration on a decent

wide powerband is starting to pay off. The effect of the cams, porting and exhaust on the overall power is very obvious.

Compare the street bike curve with our 748 SPS from 1999(hyper) the changes in the shape of

the curve are very obvious. The effect for the racer is the same, change up a gear and you can see that you would still have over 115 bhp under your hand. No wonder the bike was fast.

Gearbox:

58.03.31 Transmission/Gearbox

- All transmission/gearbox ratios are free.

- Primary gears must remain as homologated.

- Additions to gearbox or selector mechanism, such as quick shift systems, are not allowed.

The RS includes a close ratio box, both use standard primary gearing (31/62) the R comes with

14/36 chainwheels and the RS came standard with 14/38. The ratios, on this set up are as follows, along with the overall ratio (racer in brackets).

1st teeth 37/15 =12.70 (32/16 = 10.28)

2nd teeth 30/17 = 9.04 (29/18 = 8.29)

3th teeth 28/28 = 7.20 (27/20 = 6.94)

4th teeth 26/22 = 6.06 (25/21 = 6.12)

5th teeth 24/23 = 5.35 (24/22 = 5.61)

6th teeth 23/24 = 4.93 (23/23 = 4.93)

It is easy to see the close overall grouping of the gears. It is necessary to remember that while

the racer will suffer off the line from the high first gear he can use the lowest gears several times a lap. It is not easy to change the gearbox so unlike 125/250 GP racers we are pretty much stuck

with the basic box. To make best use of the power and to get the best chassis set up (see the next section) we can use all six gears, the first five or the last five, confused yet? Good 'cos so am I.

We can change rear sprockets of course, we have a range of 14 to 16 front and 36 to 43 rear.

From memory the highest we have run is 15/38 at Thruxton, where Paul got the bike through the speed trap out on the fast bit of the circuit fastest….(the fast bit speed trap is mid very very fast

corner, so make that 140mph plus with the right knee firmly planted on the track)

The role of the gearbox is more closely related to putting pressure on the suspension mid corner

than maintaining accelleration these days, but it is worth noting just how close the standard R gearbox is to start with. This box is standard in all the 748 and the SP and SPS 916/996's also.

(916/996 Bips have a much higher 6th gear, their fifth gear being the same as the 748R's sixth.)

The Chassis:

58.03.1 Frame Body and Rear sub frame

- Frame must remain as originally produced by the manufacturer for the homologated

machine.

58.03.3 Rear Fork (Swing arm)

- The rear fork must remain as originally produced by the manufacturer for the homologated

machine. A chain guard ('shark fin') must be fitted in such a way as to prevent trapping between the lower chain run and the final drive sprocket at the rear wheel.

- Rear fork pivot bolt must remain as originally produced by the manufacturer for the homologated machine.

- Rear axle adjuster (chain adjuster) must remain as originally produced by the manufacturer for the homologated machine.

58.03.4 Rear Suspension Unit

Rear suspension unit can be changed but a similar system must be used (i.e. dual or

mono), using the original attachments of the frame and rear fork (swing arm).

- Rear suspension unit spring(s) may be changed.

- Rear suspension linkage must remain as originally produced by the manufacturer for the homologated machine.

58.03.5 Wheels

- Wheels must remain as originally produced by the manufacturer at the time of sale into the

dealer/distributor network for the homologated machine.

- The speedometer drive may be removed and replaced with a spacer.

- If the original design included a cushion drive for the rear wheel, it must remain as originally produced for the homologated machine.

- Front and rear wheel axles must remain as originally produced by the manufacturer for the homologated machine.

- Wheel diameter and rim width must remain as originally homologated.

This lot effectively means you are going to be racing a standard motorcycle with only modified damping and springing. The Ducati however has a bunch of other adjustments. Rear ride height rod, rear axle position, front fork up or down front fork 24.5deg or 23.5 deg.

Every rider and every circuit requires a different combination, the more competitive the series the closer to perfection you need to be to be competitive. Some of Paul's preferences were

completely different to last year but we had fifteen more horsepower and were running as much as three seconds a lap faster.

We built our own fork pistons (Paul tried three types before he settled for a favourite) and several shim set-ups. Although we had several choices standard springs did most of

the work on the front all year. The rear was a bit different with rear spring and ride height choice making more difference than any other adjustment. We built our own fork pistons (Paul tried three types before he settled for a favourite) and several shim set-ups. Although we had several choices standard springs did most of

the work on the front all year. The rear was a bit different with rear spring and ride height choice making more difference than any other adjustment.

To give you an idea of the extremes that are available you need to look closely at the rules.

58.03.4 above means that the rear suspension has to use the rising rate linkage designed not to dent your kidneys when you hit a pothole in the road on the way to the shops. This is less

than helpful when a rapid increase in spring or damping rate is the very last thing you want when you have the tyre rolled round the side of the

rim mid corner. It would simply overload the tyre and grip would go, if you are lucky or skilled you might not crash.

The Ducati Superbikes solve this with a choice of several different linkages. We cannot do that.

We have a very nice Ohlins shock that is valved to reduce the effects of rising rate as much as possible, it also has a big oil/gas reservoir to stop the compressed gas in the shock adding to the

rising rate effect. We use straight rate springs and the chassis attitude/preload/spring rate combination is designed to work in the part of the suspension stroke that is not affected by the

rising rate too much, very rarely do we see bottoming.

I am not going to talk specific numbers here (there have to be a few trade secrets left!!) but it is

fair to say that the biggest amount of work in these chassis' is the balance that needs to be maintained with gearing and chassis set up. Because of the eccentric rear wheel adjustment a

tooth on or off the back raises or lowers the rear sufficiently enough to change the handling of the bike. Change four teeth (like shall we set it up to race with five gears or all six) and you could

spend a day to restore the handling on the limit. Again in Superbike they can use a choice of three different primary drive gears to help change overall gearing, and to allow them to remain

closer to the chassis 'sweet spot' when changing rear sprockets.

This is all before we consider the different fork oil heights and damping clicker adjustments that

are used. The amount of time that can be wasted chasing the best chassis set up is amazing; the cost of that time is also amazing. There is no point testing at anything less than full race speed so

two hours of testing costs just as much as the two hours of practice and race time that we get in a typical British championship race weekend. I calculate that we see an average of 100 miles in

every hour of track time, that's 150km or thereabouts, so five hours of full speed track time is enough to require a full engine rebuild. One of those includes valves, closing rockers, barrels,

pistons and rods and the time to build it right.

Two years of racing Sport Production and Supersport have left us with a mine of knowledge on

the way standard chassised Ducati's operate at all levels of racetrack use, they are unbelievable when they are right but they can feel awful if you get it wrong.

The best circuit in the UK to compare with all out road use is Oulton Park, just over three miles of

bumpy, flat out bendy track, its got hills dips, open corners and flat out blind ones. The circuit requires good low and high-speed acceleration, compliant suspension and stable handling. It is

more like a flat out public road road blitz than any other circuit I know. These are our May 2000 practice times and speeds, nuff said. (Click on sheet to zoom in for a closer look!)

Neil Spalding

|